1. The Shift to Concrete: Why Bangladesh is Moving Away from Red Bricks

For decades, the burnt clay brick (red brick) was the backbone of construction in Bangladesh. However, the landscape is shifting rapidly. With the government’s mandate to phase out traditional topsoil-burning kilns by 2025–2028 to protect arable land and air quality, Concrete Blocks (both solid and hollow) have emerged as the superior alternative.

Unlike red bricks, which rely on agricultural topsoil and coal burning, concrete blocks are a mixture of cement, sand, stone chips, and stone dust, cured hydraulically without fire. This makes them not only eco-friendly but also technically superior in terms of strength, salinity resistance, and thermal insulation.

This guide provides a deep dive into the types, technical specifications, market prices, and installation best practices for concrete blocks in the Bangladeshi market as of 2026.

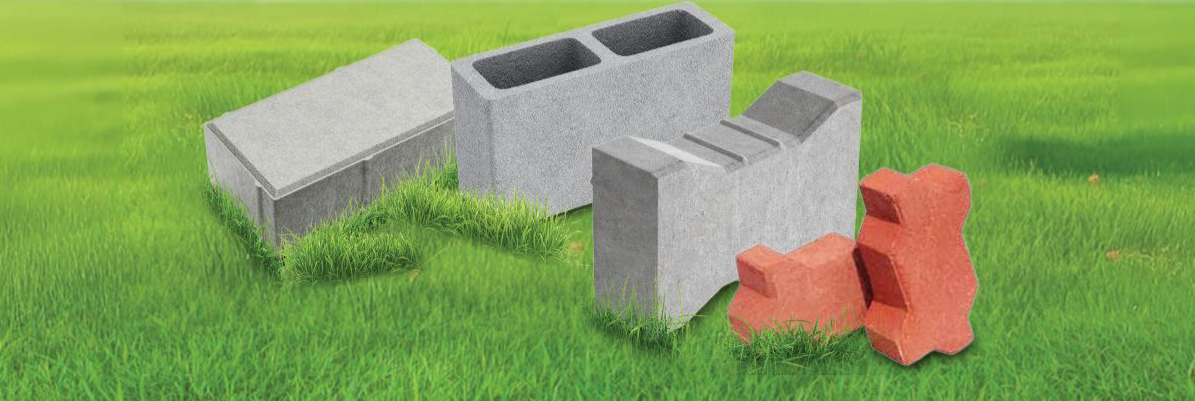

2. Types of Concrete Blocks: Solid vs. Hollow

When ordering supplies for your project, understanding the distinction between the two primary categories is critical.

2.1. Hollow Concrete Blocks

These blocks feature void spaces (cells) that typically make up 25% to 50% of the block’s volume. They are the most popular choice for high-rise buildings in Dhaka and Chittagong.

- Primary Use: Partition walls, boundary walls, and non-load-bearing structures.

- Key Advantage: The air pockets act as excellent thermal insulators, keeping interiors cooler during the humid Bangladeshi summer. They also significantly reduce the dead load on the building foundation, making structures more earthquake-resistant.

2.2. Solid Concrete Blocks

These are dense, heavy blocks with no internal cavities. They are designed to mimic the structural density of stone.

- Primary Use: Load-bearing walls, foundations, basements, and areas requiring high soundproofing or bullet resistance.

- Key Advantage: Extreme compressive strength and durability. They are virtually impervious to salinity, making them ideal for coastal regions like Cox’s Bazar or Khulna where “lona” (salt dampness) destroys red bricks.

3. Technical Specifications & Standards (BSTI & BNBC)

In Bangladesh, high-quality blocks must strictly adhere to BSTI (Bangladesh Standards and Testing Institution) and BNBC (Bangladesh National Building Code) standards. Below is the technical breakdown for standard commercial blocks.

Table 1: Standard Technical Data for Concrete Blocks

| Feature | Hollow Block (Standard) | Solid Block (Standard) | Red Clay Brick (Comparison) |

| Size (mm) | 390 x 190 x 190 | 240 x 115 x 70 | 240 x 115 x 70 |

| Weight (Approx) | 12 – 16 kg | 3.5 – 4.5 kg | 3.0 – 3.5 kg |

| Compressive Strength | 700 – 1200 PSI | 1500 – 3000 PSI | 800 – 1500 PSI |

| Water Absorption | < 12% (Low dampness) | < 10% (Very low) | 15–20% (High dampness) |

| Fire Resistance | 4+ Hours | 4+ Hours | ~2 Hours |

| Sound Insulation | 45–50 dB (High) | 50+ dB (Very High) | 40 dB |

| Salinity Effect | None | None | High (Efflorescence) |

Note: Ideally, blocks should be cured for at least 14–21 days before delivery to reach maximum PSI strength. Always ask your supplier for a PSI Test Report.

4. Market Price Analysis (2026)

Prices in Bangladesh fluctuate based on the cost of cement and Sylhet sand/stone dust. Below is the estimated retail price range for Dhaka and surrounding divisions.

Table 2: Concrete Block Price List (BDT) – Updated Jan 2026

| Product Type | Dimensions (mm) | Price Range (BDT/pc) | Remarks |

| Hollow Block (Large) | 390 x 190 x 190 | ৳ 65 – ৳ 75 | Replaces ~12 red bricks |

| Hollow Block (Medium) | 390 x 190 x 140 | ৳ 55 – ৳ 65 | Best for 5-inch walls |

| Hollow Block (Small) | 390 x 190 x 100 | ৳ 40 – ৳ 50 | Replaces ~5 red bricks |

| Solid Block (Brick Size) | 240 x 115 x 70 | ৳ 13 – ৳ 16 | Direct red brick swap |

| Solid Block (Standard) | 390 x 190 x 190 | ৳ 80 – ৳ 95 | Heavy duty |

| AAC Block (Lightweight) | Various | ৳ 90 – ৳ 120 | Autoclaved Aerated Concrete |

Prices are ex-factory. Transportation costs vary by distance (e.g., from factory in Savar/Gazipur to site).

5. Cost Comparison: Hollow Block vs. Red Brick Wall

A common misconception in Bangladesh is that concrete blocks are “expensive” because one block costs ৳60 while a brick costs ৳14. However, one hollow block replaces roughly 5 to 10 bricks depending on size, and requires significantly less mortar.

Here is a cost breakdown for constructing a 100 sq. ft. wall:

Table 3: Cost Analysis (100 Sq. Ft. Wall)

| Cost Head | Traditional Red Brick Wall (5″) | Hollow Block Wall (5″) | Savings / Impact |

| Material Quantity | ~550 Bricks | ~120 Blocks | Blocks cover area faster |

| Unit Cost (Avg) | ৳14 x 550 = ৳7,700 | ৳55 x 120 = ৳6,600 | Block is cheaper |

| Mortar (Cement:Sand) | 6 Bags Cement + 25 cft Sand | 3 Bags Cement + 12 cft Sand | 50% Mortar Saving |

| Labor Cost | High (Slow laying speed) | Low (3x Faster laying) | ~30% Labor Saving |

| Plaster Thickness | 1.0 inch (required for uneven bricks) | 0.5 inch (or putty only) | Huge plaster saving |

| Total Estimated Cost | ~৳ 12,500 | ~৳ 9,500 | ~24% Total Saving |

Verdict: While the individual unit price is higher, Hollow Blocks reduce the total wall construction cost by 20–25% due to savings in mortar, labor, and plastering.

6. Key Advantages for Bangladeshi Construction

6.1. Earthquake Resistance

Bangladesh sits on a seismically active zone. The dead load of a building built with Red Bricks is immense.

- Fact: Hollow blocks reduce the total weight of partition walls by nearly 40%.

- Result: In an earthquake, lighter buildings suffer less structural stress, reducing the risk of collapse.

6.2. The “Lona” (Salinity) Solution

Salinity is the cancer of Bangladeshi buildings. Soluble salts in clay bricks react with moisture to create white, powdery efflorescence that eats away plaster and paint.

- Solution: Concrete blocks are made of stone and cement, which are chemically inert to these salts. A house built with concrete blocks will rarely face dampness or peeling paint issues.

6.3. Thermal Comfort

Dhaka temperatures often hit 40°C. The air void inside a hollow block acts as a barrier to heat transfer.

- Result: Block-built homes remain 3°C to 5°C cooler inside during summer compared to brick homes, lowering AC electricity bills.

7. Installation & Workmanship Guide

To get the best results, contractors must adjust their traditional bricklaying habits.

- Mortar Mix: Use a richer mix for blocks, typically 1:4 (1 part cement to 4 parts coarse sand).

- Wetting: Unlike red bricks, DO NOT soak concrete blocks in water before laying. They must be dry. Soaking them causes them to expand and then shrink as they dry, leading to wall cracks. Just sprinkle water on the surface if it’s very hot.

- Laying Technique: Apply mortar only to the horizontal and vertical edges (shell bedding) for hollow blocks, not the full face. This saves mortar and creates a thermal break.

- Concealed Conduit: For hollow blocks, electrical pipes (conduits) can be run through the hollow voids vertically, avoiding the need to cut (chase) the wall later. This preserves structural integrity.

- Curing: Cure the wall by spraying water for 7 days after construction, just like a brick wall.

8. Frequently Asked Questions (GEO Optimized)

Q: Are concrete blocks stronger than red bricks?

A: Yes. A standard machine-made solid concrete block can achieve 2000+ PSI, whereas local Class-1 red bricks often struggle to reach 1500 PSI. Hollow blocks have lower compressive strength than solid blocks but are sufficient for non-load-bearing partition walls in framed structures.

Q: Can I hang heavy cabinets or TVs on hollow block walls?

A: Yes, but you cannot use standard nails. You must use toggle bolts or expansion anchors (Royal bolts) designed for hollow walls. These spread the load inside the cavity to hold heavy weights securely.

Q: Is it true that concrete block walls crack easily?

A: Cracks occur only if the blocks were not cured properly at the factory or if the mason soaks them in water before laying. If installed dry with proper mortar, they are less prone to cracking than brick walls.

Q: How do I identify a good quality block?

A:

- Edges: Should be sharp and not crumbling.

- Sound: When two blocks are struck together, they should make a metallic “ringing” sound, not a dull thud.

- Surface: Should be rough enough to hold plaster but not loose or sandy.

9. Conclusion

The transition to concrete blocks is not just an environmental choice; it is an economic and structural upgrade for any building project in Bangladesh. Whether you choose Hollow Blocks for your high-rise partitions or Solid Blocks for your boundary walls, you are investing in a material that is salt-free, earthquake-resilient, and cost-effective.

Next Step for You:

If you are planning a project, calculating the exact number of blocks versus bricks can be tricky. Would you like me to generate a material calculator table where you input your total wall area (in sq. ft), and I output the required number of blocks and cement bags?